Fetch Robotics’ Autonomous Mobile Robots (AMRs)

Freight100 (100kg payload) is the base of the Fetch Mobile Manipulator but it was designed to be a modular platform. Various attachments can be mounted to satisfy specific material handling workflows. The visual language was again to be friendly and approachable yet capable and durable. We were determined to facilitate human/robot collaboration and to achieve mass acceptance of a new robotic coworker.

The HMIShelf was the simplest solution and was the first attachment to be deployed. The touch screen allowed for point A to point B delivery at the touch of a button. CartConnect is as it sounds – the Freight100 attaches to a cart, delivers it from point A to point B, and detaches from the cart at its destination. RollerTop interacts with stationary conveyor belts. TagSurveyor has three RFID antennas which assist in inventory tracking. FlexShelf Guide and RollerTop Guide are specifically for fulfillment applications. They meet a picking associate at the specific item to be picked in an e-commerce warehouse. Freight500 and Freight1500 (500kg and 1500kg payload respectively) will also perform CartConnect solutions along with transferring pallets and crates from one pick-up/drop-off station to another.

First version of Freight500 and Freight1500

For the first iterations of Freight500 and Freight1500, we went a little more aggressive with the design but maintained the visual language. Also, apposed to injection molded covers on Freight100, we went with all sheet metal covers. This provided for a more durable robot to work with forklifts while allowing us the freedom to iterate on the design and functionality inexpensively. The design was short-lived however. The lasers were centered on the front and rear which created triangular blind spots on either side of both robots.

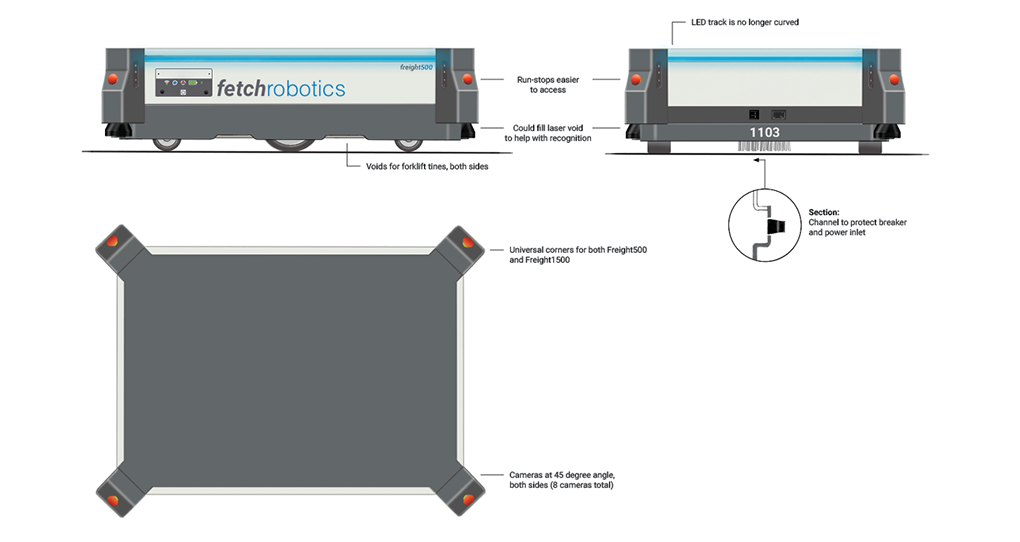

Updated Freight500 and Freight1500

The second version or Freight500 and Freight1500 has the front and rear lasers relocated from the center to opposite corners to achieve 360 degrees of coverage. The footprint also became rectangular which helped reduce the bill of materials. Both robots have the same corner assemblies with the front/rear, right/left side panels only changing in length.